Our die casting services include a wide range of capabilities, allowing us to meet a variety of industrial challenges. We offer:

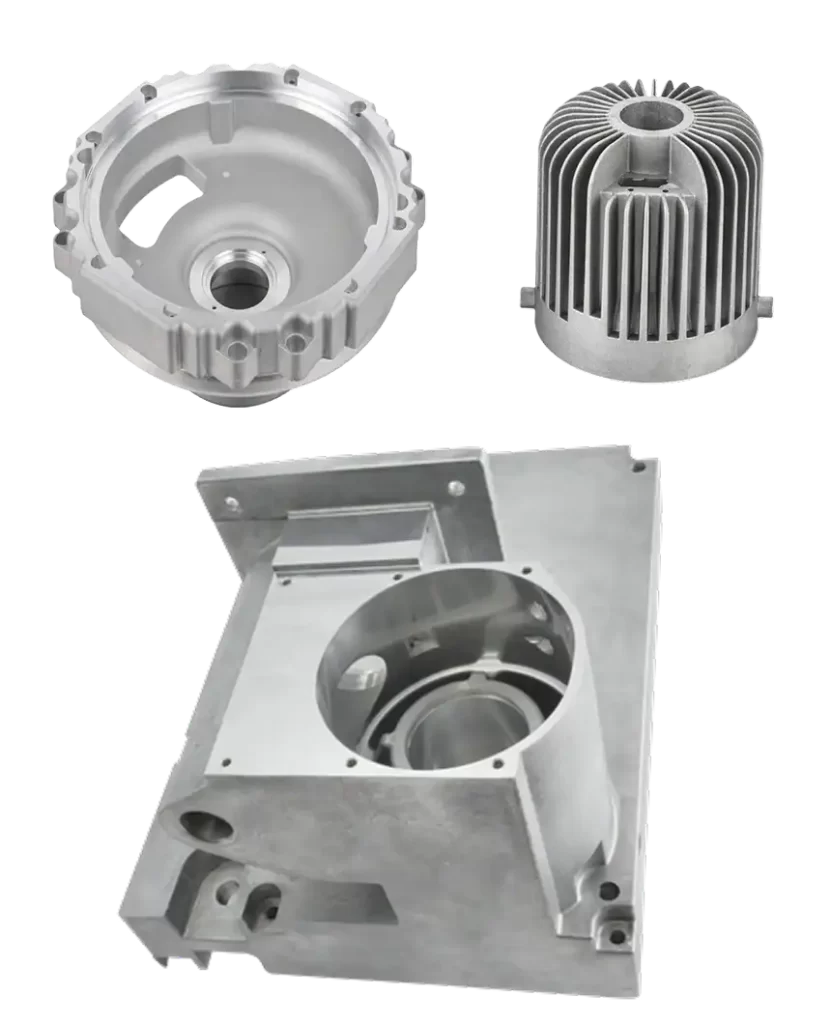

High-Presuure Die Casting (HPDC): Utilizing both hot chamber and cold chamber technologies, we produce complex metal parts with excellent dimensional accuracy and repeatability.

Aluminium Die Casting: Lightweight yet strong aluminum components ideal for automotive, aerospace, electronics, and medical industries.

Zinc Die Casting: Durable zinc parts with excellent surface finish and high precision for complex geometries.

Magnesium Die Casting: High-strength components with reduced weight, perfect for applications requiring strength-to-weight optimization.

To complement our die casting capabilities, we offer precision CNC machining services. Our machining centers enable us to achieve tight tolerances and intricate detailing on cast components. Additionally, our finishing options include:

Surface treatments (anodizing, powder coating)

Sandblasting

Painting & coating

Assembly & subassembly operations

We understand that different applications demand specific material properties. To accommodate this diversity, we specialize in several key alloys:

Aluminum Alloys (ADC12, A380): Known for lightweight strength, corrosion resistance, thermal conductivity; widely used in automotive parts.

Zinc Alloys (Zamak 3, Zamak 5): Excellent castability with high dimensional stability—ideal for precision components in electronics and consumer goods.

Magnesium Alloys (AZ91D): Offering exceptional strength-to-weight ratios suitable for aerospace and automotive industries.