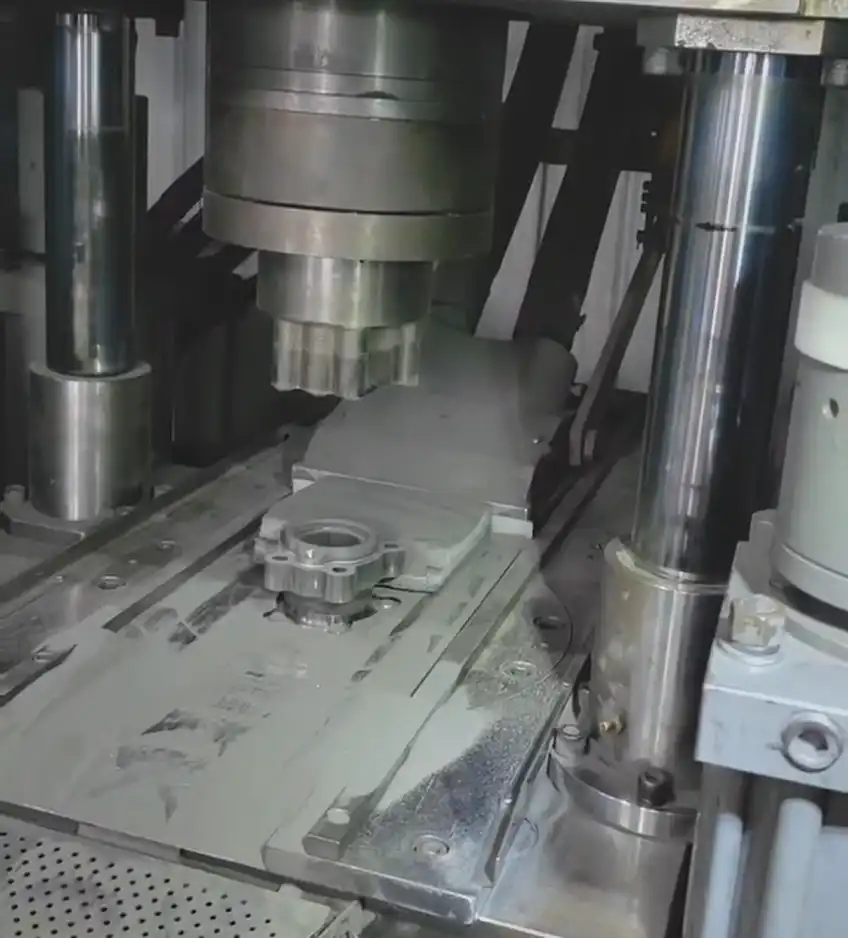

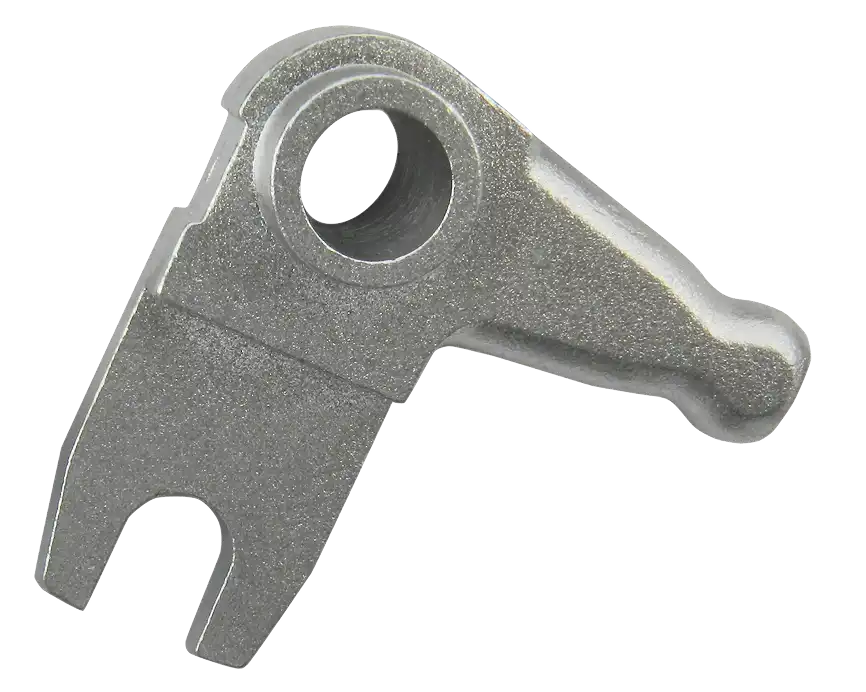

This time-tested method is our go-to for large-scale production of durable structural components. The process involves:

Our traditional powder metallurgy technique is especially effective for:

MIM technology merges the versatility of plastic molding with the robustness of metal fabrication. This innovative process excels in crafting intricate, compact parts with exceptional precision. MIM is particularly advantageous for industries demanding miniaturization and accuracy, such as:

Our MIM process ensures cost-effective mass production while maintaining perfect quality and dimensional stability.

Our cemented carbide products are sturdy and wear-resistant metal parts. Composed of tungsten carbide particles bonded with cobalt, these materials offer exceptional hardness (1400-2000 HV), superior wear resistance and extended tool life in demanding applications.

Cemented carbides find extensive use in:

Hydroforce Engineering manufactures a wide range of finished and semi-finished tungsten carbide products for our customers.

Designing and producing custom porous metal filters for diverse applications. Our sintered filters offer:

Our filters perform reliably in demanding industries such as: